JANOME JP 5 Servo Press

Higher Speed & Greater Precision and Enchanched Interfacing

Main Features

Basic Informations

01 Easy Installation

- Ethernet port included as standard equipment.

- Choose from 6 different Fieldbus types.

- Low noise and clean work environment.

- Much lower running cost than oil or air presses.

- Easy program teaching.

02 Faster ram movement for higher productivity

Maximum ram speed up 2.5x, ram acceleration up 3.5x over our previous model. Best speed in the industry for lightweight presses, therefore greatly reduces cycle time.

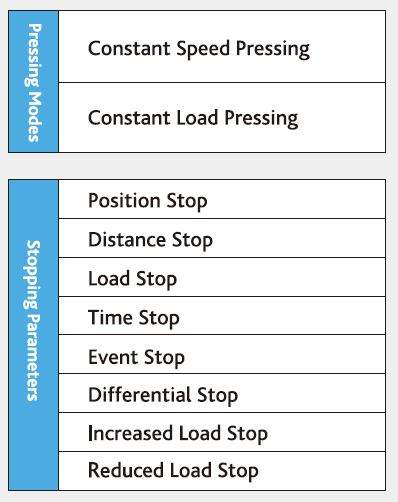

03 A rich variety of both pressing and sensor functions

Choose from among these pressing modes and stopping parameters.

Sensor functions

of the program and is not influenced by divisions between pressing steps.

04 Improved product quality

Internal processing speed up 4.0x over our previous model.

Load Precision: ±0.8% (FS) *1

*Value range from 5% or more of the maximum load.

*1 This is the level of precision when measured in indentical working conditions.

Repeatability: ±0.005mm*2

*When the press unit is at a constant temperature

05 Global Diagnostic Funcionality

Comprehensive hardware diagnostics including PC boards. It’s easy to switch among display languages, so thus it could be really helpful in multinational workplaces, where engineers and operators use different languages!

PC software Languages:

- English

- Japanese

- Korean

- Chinese (Simplified & Traditional)

Teaching Pendant Languages:

- English

- Japanese

- Korean

- Chinese (Simplified & Traditional)

- Vietnamese

- German

- French

- Spanish

- Italian

- Romanian

- Czech

06 Auto Amp Adjustment ・Auto Load Calibration

Now you can perform complicated load calibrations automatically.*2

*2 Please consult with us about compatible load cells

07 System Configuration

Ideal for the „IoT Era” visualized workplace.

Smoothly incorporate into your facility, for easy quality control.

PC Software

Compatible with desktop, laptop and HMI(touch panel) PCs; choose the PC setup suitable for your facility.

01 JP-5 Designer Create, edit, send and receive teaching data.

Create teaching and sensor parameter data, send and receive all your setting data to and from your PC, save changes, backup and print your data.

- Upload teaching data from the Electro Press to your PC.

- Create and edit teaching data and send it to the Electro Press.

- Save teaching data on your PC and print it out.

- Acquire time series data via JP5 Sampler and display it as a graph.

- Edit sensor conditions, etc. based upon graphic displays.

- Real time I/O monitoring during press operation.

02 JP-5 Sampler (Optional) Receive and save pressing result data.

Use this software to display quality control data and time series data for each shot and save it as a sampling file. Displays the pressing results for multiple press units on one screen.

- Upload run result data to your PC (minimum sampling interval 0.25msec).

- Display quality control data in list display format, and time series data as a graph.

- Output sampling data in CSV/TXT file format.

- Collect run result data from multiple presses.

03 JP-5 Reporter (Optional) Analyzes saved result data and creates reports.

Display data acquired by Sampler, generate CPK analysis and result analysis reports.

- Use quality control data to calculate and display statistical averages and standard deviations.

- Display the frequency distribution (histograms) for end load values and end positions.

- Display CPK (process capability index) data based upon run result data.

- Display operational status program by program. (Error rate, no. of OK/NOK, average cycle time, average prep time, etc.)

- Make reports in HTML format.

Industrial Application

- Specifications may be modified without prior notice to improve product quality.

From press fitting to testing, the Janome Servo Press has an important role in many different processes.

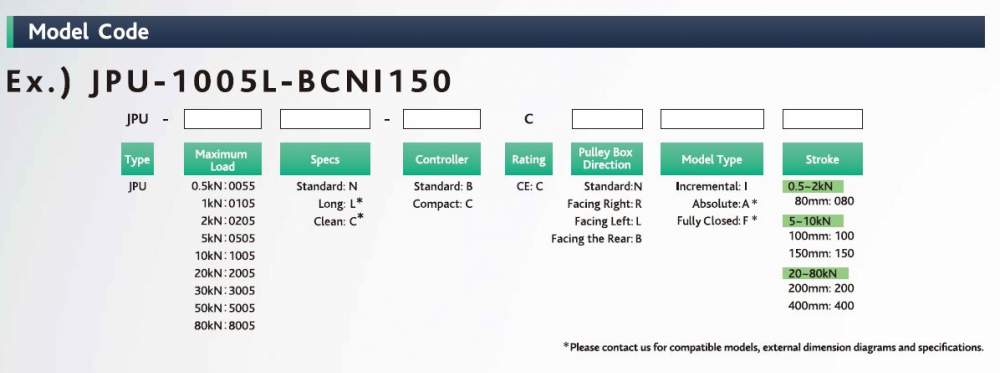

How to Read the Model Code

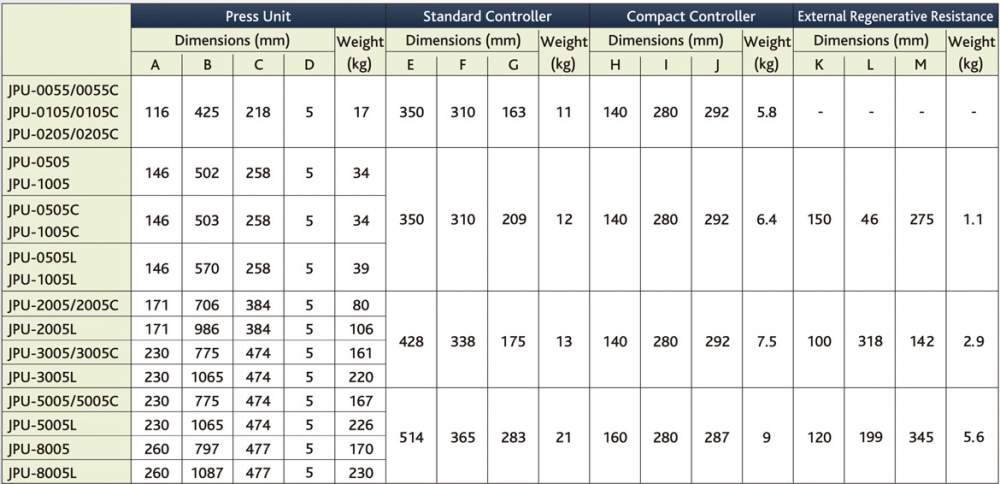

External Dimensions

- With the Compact Controller, the Regenerative Resistance in an external add-on.

- Regenerative Resistance is standard for JPU-0505 and above.

- For more details about dimensions, etc. please contact us.

Specification

- *1 Recommended setting range.

- *2 Value when making a cold start. This may also change due to setting conditions.

- *3 Load Display precision is ±0.8 % (FS) of the maximum load when pressing in the range of 5% or more of the maximum load. This is an indicator of sensor measuring unit and accuracy and is not an indicator of load tolerance after pressing or margin of error. Precision also dependent upon there being no influence from increases in temperature.

- *4 Position repeatability is dependent upon the press bearing a constant load at constant press unit and surrounding environmental temperatures. Repeatability is not a guarantee of absolute position precision.

- *5 The clean class indicated above is based upon ISO-14644-1 and upon United States Federal Standard 209D (FED-STD-209D). The Compact Controller is Standard Type only; it is usable with a Clean Room Model press, provided the Compact Controller is installed outside of the clean room.

Common Specification

- *1 The number of programs, pressing steps and step judgements is limited in relation to the total memory size. When multiple steps are included in one program, this in turn limits the number of new programs which can be added to the memory.

- *2 Optional internal I/O Power Supply available for the Standard Controller.

- *3 Please contact us for operating specifications and compatible models.

Accessories

- JP-5 Designer PC Software (Windows® 7, Windows® 8.1, Windows® 10, Microsoft Windows® Embedded Standard 7 WS7P compatible)

- Operation Manual (CD-ROM)

- Press Unit Connector Cables (3m) (Optional Lengths:5m/10m/15m/20m)

- SWBOX Short Connector

- TPU Short Connector

- I/O-S Short Connector

- I/O-SYS Connector

Optional

- Teaching Pendant (with Emergency Stop Switch/Sub-Switch) (Cable Lengths: 3m/5m)

- Maintenance Box (Cable Lengths: 3m/5m)

- JP TaS II SYSTEM PC Software (Windows® 7, Windows® 8.1, Windows® 10, Microsoft Windows® Embedded Standard 7 WS7P compatible)

- I/O-SYS Cable (2m/3m/5m)